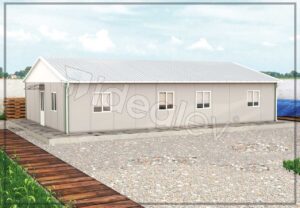

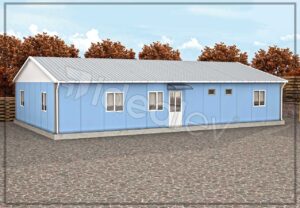

You can find Prefabricated Office Models and Prices on this page.

Prefabricated offices are office buildings created by assembling modular building elements previously produced in factories on site in an easy and fast way to assemble. These types of structures offer many advantages over traditional construction methods. Here is detailed information about prefabricated offices:

Advantages of Prefabricated Offices;

Fast Construction Process:

Since prefabricated offices are produced in the factory, the construction time on the site is considerably shortened. This significantly reduces project completion time and reduces labor costs.

Cost Effectiveness:

Mass production of materials and rapid assembly reduces costs. In addition, the short construction period saves on labor and general expenses.

Flexibility and Portability:

Since prefabricated offices have a modular structure, they can be expanded or reduced as needed. They can also be disassembled and reassembled in another location if they need to be moved.

Eco-Friendliness:

Prefabricated buildings create less construction waste and less environmental impact. They can also be built using energy-efficient materials.

Quality control:

Stricter quality control may be applied during production in the factory. This ensures that the building elements comply with standards and are of high quality.

Usage areas

Construction Site Offices:

It is used to meet the need for temporary office space in construction projects.

Permanent Office Buildings:

It can be used as permanent business offices, administrative buildings and administrative centers.

Mobile Offices:

It offers portable office solutions for companies serving in different locations.

Emergency Offices:

It quickly meets temporary office needs after natural disasters or other emergencies.

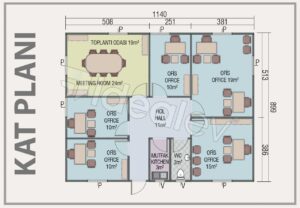

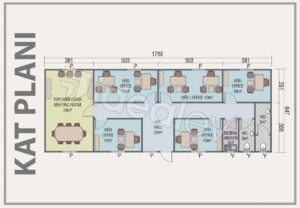

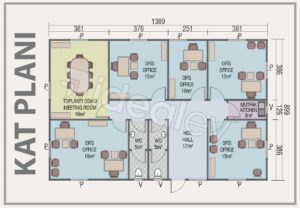

Prefabricated Office Types

Modular Prefabricated Offices:

Structures created by combining several modules. Modules can be produced in various sizes and shapes.

Panel System Prefabricated Offices:

Systems using steel or aluminum panels. These systems can have high insulation properties.

Container Offices:

Structures obtained by converting containers used in maritime transportation into office space. These offices are advantageous in terms of durability and portability.

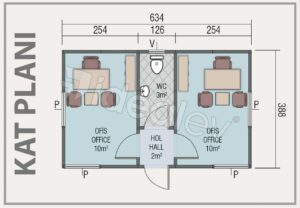

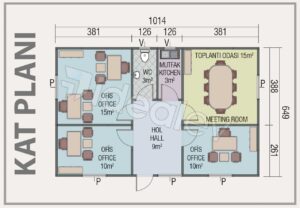

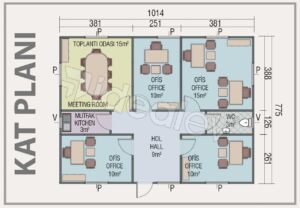

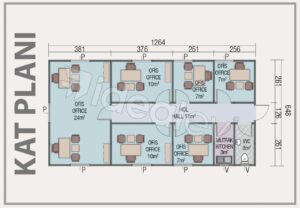

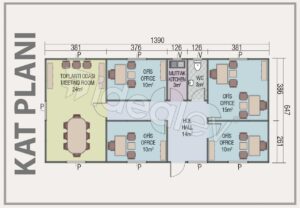

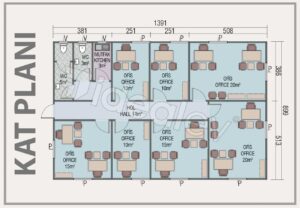

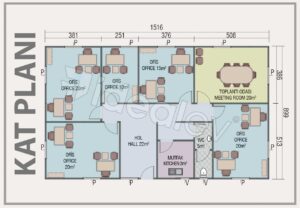

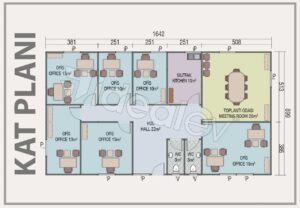

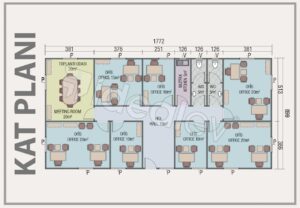

Construction Process Planning and Design:

The prefabricated office is designed in line with the needs and requests. At this stage, the size of the office, its interior layout and the materials to be used are determined.

Factory Production:

The approved design is produced in the factory environment. Modules, panels and other components are prepared at the factory.

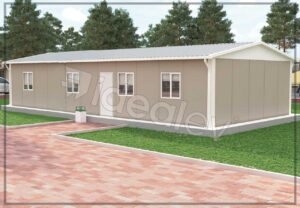

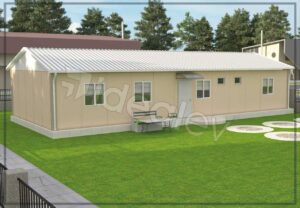

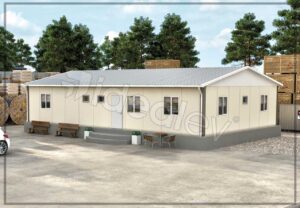

Transportation and Assembly:

The produced components are transported to the construction site and assembled on-site. This phase is completed much faster than traditional construction.

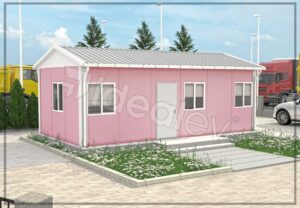

Internal and External Arrangements:

After the assembly of the building is completed, internal and external arrangements are made. Electricity, plumbing and other interior arrangements are carried out.

Examples and Applications Small Businesses:

It offers cost-effective and fast-to-install office solutions for small businesses in the early stages.

Large Corporate Structures:

Large companies can use prefabricated offices as a temporary or permanent solution. It offers fast and flexible solutions for large projects or campuses.

Conclusion

Prefabricated offices offer flexible and cost-effective solutions that adapt to the fast-paced and changing needs of the modern business world. Thanks to their wide application areas and various advantages, prefabricated offices are increasingly preferred today.