REFERENCES

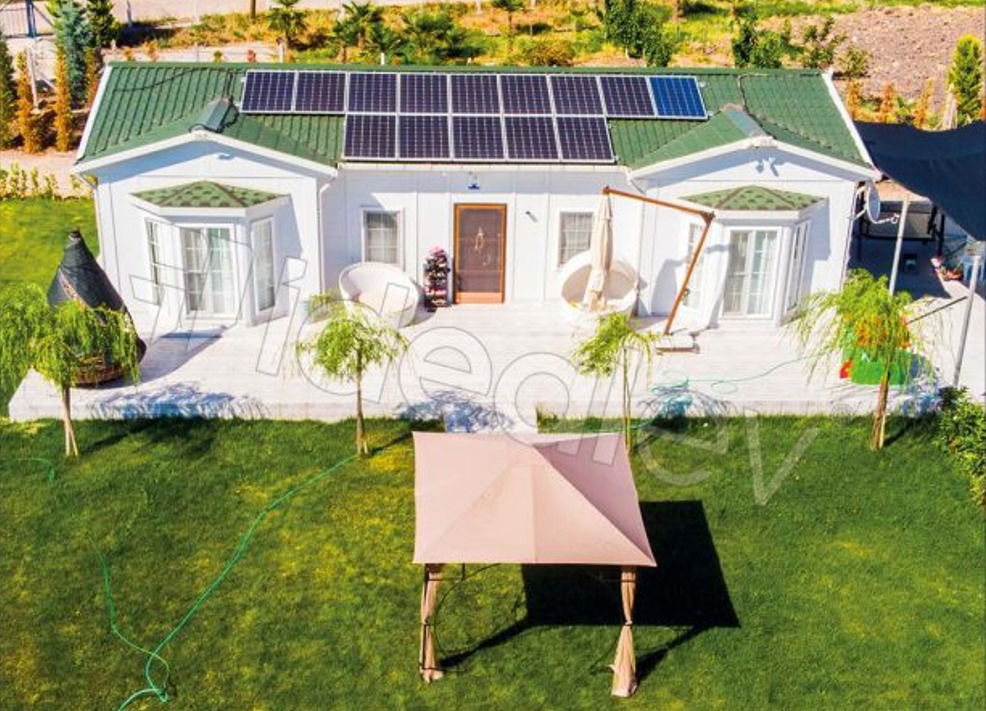

A Prefabricated House Purchase Story – Balikesir Gonen

Hello everyone,

From now on, we will share the purchasing process in our "News from Us" section, where we will tell you how the prefabricated houses we built were built and installed from start to finish.

Year 2018, on a warm Ramadan day in June, our prefabricated house customer from Balikesir, while researching prefabricated house companies on the internet, is on Instagram (https://www.instagram.com/prefabrikevimcom/) comes across the houses we have built and says he likes it very much and says he will visit you. Our customer, who is a very researcher, decides that we are the right address after visiting a few companies. And he tells us about the project he wanted. It examines the products in detail. He tells in detail what he wants to use, and we first draw him in 2D, determine the technical features and present his project.

He decides on the 98+2 prefabricated house project of 3 m1, which is one of our best-selling models in the picture you see in the project.

And in addition, it wants the following features in the building,

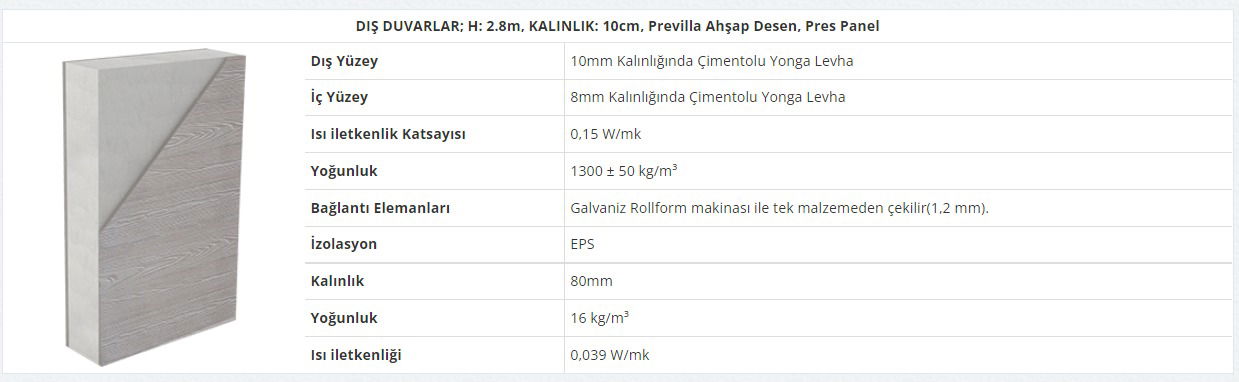

- Exterior will be 2.80 height with wooden pattern.

- The windows will be double opening, tiled.

- There will be extra OSB + Membrane + GREEN Metal Tile on the roof.

And we made a contract with our customer on a Ramadan day, we have one-tenth of this contract, which is in two copies.

And our contract was signed by both parties.

Our customer paid 80 percent of the building.

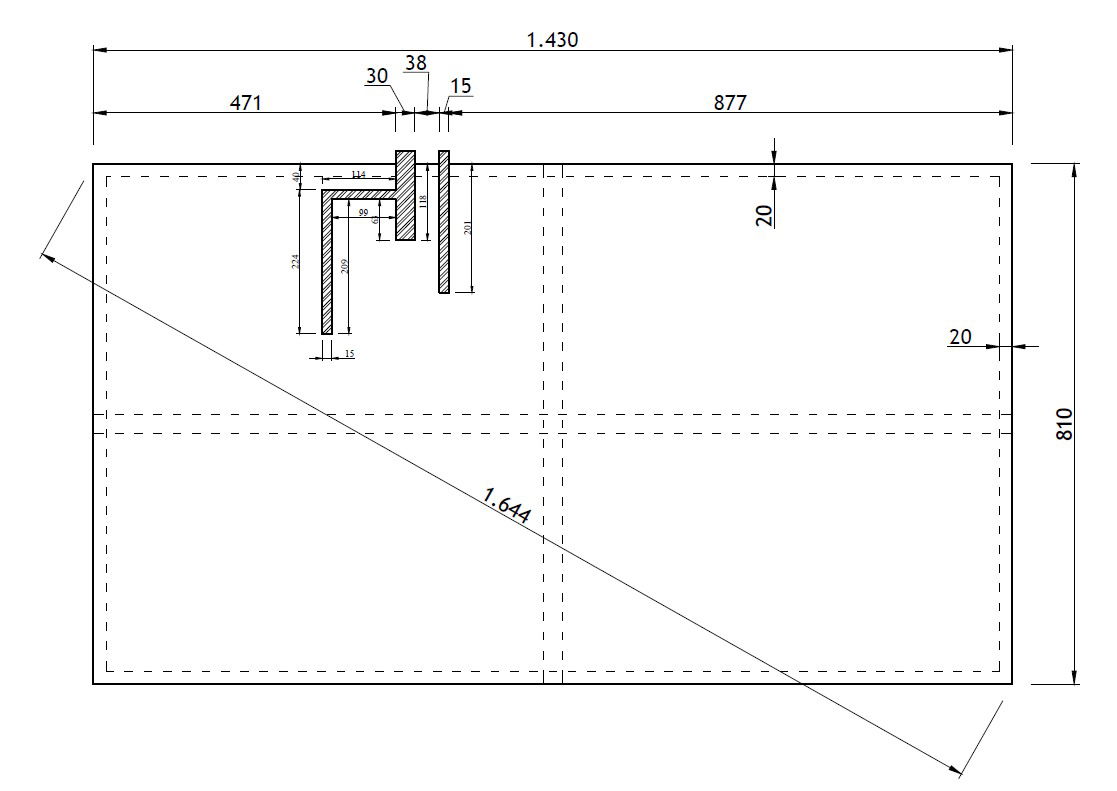

After agreeing on these features, we gave the concrete plan below according to our customer's request.

According to this concrete plan, the room cast its concrete in a balanced way.

How to throw prefabricated house floor concrete? You can click to learn.

Afterwards, our customer called us after he poured 50 cm of concrete and said, "Our concrete work is done, we are waiting for the assembly."

We sent our assembly team and prefabricated house materials, and an assembly team consists of 5 people on average.

Our customer has arranged a suitable hostel and restaurant in Balıkesir Gonen for the assembly team.

After this adjustment, our craftsmen and our prefabricated house material came to the site at 8 am. While the material was being unloaded in the field, our customer supplied the clawed jcb, which is used as a forklift, for 2-3 hours, which can be found all over Turkey.

And since there is no electricity at the assembly site, he arranged for us a 7.5 kW generator. And our masters unloaded the material from the transport vehicle within 2-3 hours with jcb.

And our customer paid the remaining 20 percent when the material was downloaded. (All payment completed.)

After the material was downloaded, our craftsmen started the installation of the prefabricated house, as you can see below,

They carried out the assembly of this 98 m2 house in 5 days.

What has been done with this house, which is an advanced rough installation;

- Installation of Prefabricated House Materials

- Installation of Prefabricated House Interior and Exterior Doors

- Installation of Prefabricated House Windows (Double Glass PCV)

- Removal of flush-mounted electrical and plumbing

- Installation of Electrical Fixtures

After these were done, our masters left that area and we sent them to another building installation.

If you ask what our customer did after this process, first of all, he had a screed application done inside and outside the building (with herringbone on the outside) with a size of 4-5 cm to cover the u profiles used under the building. (If desired, styrofoam can be added to the subfloor in order to prevent cold from the floor, but if styrofoam is to be added, we must be told beforehand, accordingly the door panels should be arranged.)

On the screed that dries after the screed application, our customer applied interior bathroom tiles, outdoor patio tiles, provided the sanitary ware he liked and had them fitted by the tile master.

After the tile work was finished, our customer called us, we sent our paint teams consisting of 2-3 people to our customer, these paint teams not only painted but also covered all corners of the building with mastic silicone. And the average paint and mastic took 3 days.

After the paint and mastic application, our customer has the parquet and kitchen cabinet installed. By placing your furniture in an orderly manner.

By solving the electricity problem with solar panels.

He started to live peacefully in his 98 m2 prefabricated house in Balikesir.

Now let's look at the pictures of the house and the video from the top,

If you have any questions, you can reach us on our +90 553 905 35 10 (whatsapp & viber) line. info@prefabrikevim.com is our e-mail address.